Apple has announced a new USD 100 billion investment in the United States, expanding its prior USD 500 billion domestic pledge. The announcement comes in response to escalating pressure from Donald Trump, who has demanded that Apple relocate more of its manufacturing operations to the U.S. or face substantial tariffs on imported products.

The announcement stated that the additional funds will support domestic production of Apple components, the construction of new data centers, and the establishment of a smart glass facility in Harrisburg, Kentucky. That factory will manufacture cover glass for all iPhones and Apple Watches worldwide. This marks a major shift toward US-based production.

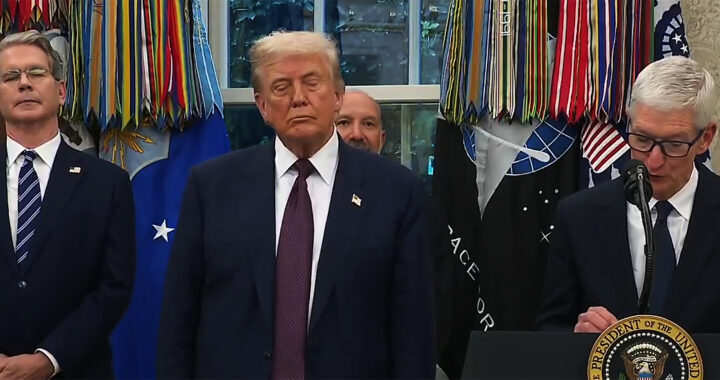

Trump praised Apple during a formal announcement at the White House on 6 August 2025. He credited the company with reshoring supply chains and avoiding a proposed 100 percent tariff on semiconductors. Trump also noted that other firms could similarly sidestep tariffs by committing to large-scale domestic investment and manufacturing operations.

Apple chief executive Tim Cook reiterated their earlier investments and emphasized the ongoing efforts to expand domestic production. He noted that the initial USD 500 billion commitment has begun delivering results and that the additional USD 100 billion will further support the manufacturing of key Apple components within the U.S. for use in global devices.

Cook presented President Trump with a glass statue assembled on the Resolute Desk in the Oval Office during the ceremony. The gesture symbolized cooperation between the company and the administration. The strategic move could help Apple avoid immediate tariff consequences and signal its willingness to meet the reshoring expectations from Trump.

Apple intends to manufacture approximately 19 billion chips within the U.S. This likely involves advanced processors and custom silicon used in iPhones, iPads, and Macs. This initiative may include collaboration with the new TSMC plant in Arizona. The reshoring of chip production is further aligned with the U.S. goals to enhance semiconductor independence.

The company also commits to purchasing only rare-earth magnets that are sourced and produced within the U.S. These magnets are essential components in Apple devices, powering internal motors in iPhones, MacBooks, and accessories. Its partnership with MP Materials reflects a broader trend of domestic sourcing for strategically sensitive materials.

White House officials claim that the pledges demonstrate that the economic agenda of Trump is persuading corporations to protect U.S. economic and national security interests. They added that the efforts would help restore the position of the U.S. as a global leader in consumer electronics and related advanced manufacturing technologies and innovation.

Caution regarding the feasibility and related costs of reshoring part of the supply chain of Apple in the U.S. has emerged. Apple currently relies heavily on Chinese assembly and has increasingly shifted operations to Vietnam and India. Replicating its vast supply chain and relevant production infrastructure domestically would be complex, time-consuming, and expensive.

It is estimated that moving production to the United States could raise iPhone prices by USD50 to USD 500 per unit in the short term. These costs would stem from higher labor rates, infrastructure expenses, and initial inefficiencies. Apple may offset these hikes using subsidies from the CHIPS and Science Act and other federal incentives for domestic production.

Apple continues to expand further its American footprint despite pressing challenges. It earlier announced a manufacturing academy in Michigan and a USD 500 million agreement to purchase rare-earth materials from MP Materials. The U.S. government has supported MP Materials through ownership stakes and price guarantees to promote supply chain resilience.